In commercial, industrial, and public-sector buildings across the UK, a hinge is more than a simple pivot point. It’s a load-bearing component that supports the full weight of the door, absorbs repeated impact, and maintains alignment through years of daily use. When a hinge is underspecified or poorly made, the effects are felt across the entire opening: latches begin to drag, frames distort, clearances tighten, and the door starts to bind. Over time, the price of that initial compromise grows far beyond the hardware itself, inflating the overall hinge replacement cost.

Read More

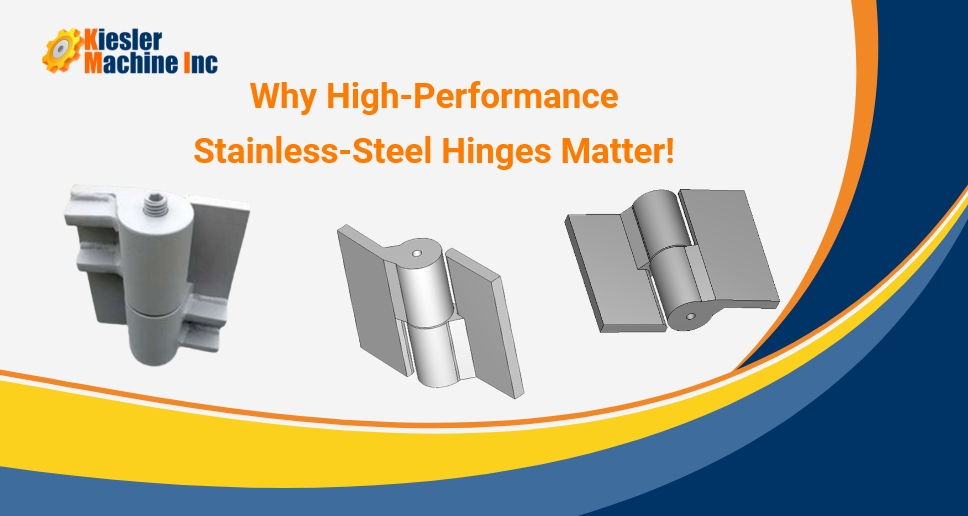

Off-the-shelf hardware is built to meet standard performance demands, and when used for its intended purpose, it will operate as designed. However, these critical system components experience extreme demands throughout industries, from heavy loads and high-use in medical facilities to blast- and tamper-resistant security applications. Standard hardware might fit the drawing, but in these situations, doors start to sag, alignment drifts, and the limits of off-the-shelf become obvious.

Read More

Steel fabricators are under constant pressure to meet tight deadlines, unforgiving tolerances, and flawless performance expectations. When projects involve heavy-duty doors, gates, access panels, or enclosures, a poorly specified or inferior hinge can lead to expensive consequences.

Read More

Heavy-duty industrial hinges are subjected to far more than simple opening and closing. In the field, they face corrosion from salt spray, chemicals, and humidity; fatigue from repeated heavy cycles; and contamination from dust, grit, and moisture. Standard off-the-shelf hinges are usually designed for general use and are often built from lower-grade steel with minimal coatings

Read More

Cancer treatment facilities across the UK and Europe demand the highest standards of safety, reliability, and compliance. Yet one of the most overlooked risks in these projects comes from something as simple as a hinge. Radiation shielding doors, secure access points, and high-use corridors all depend on hinges designed to carry extraordinary loads and function without fail. The temptation for many project teams is to specify any US-made hinge, assuming that all American manufacturing automatically guarantees quality. While it’s true that US-made products often carry a strong reputation, not every hinge labelled “Made in USA” is engineered for the specialist requirements of oncology facilities. Choosing the wrong source can introduce hidden risks that only surface once construction is underway, or worse, after the building is operational.

Read More

In demanding industrial and infrastructure projects across Europe, hardware choices often come under pressure from budget constraints and tight timelines. Hinges, in particular, are too often treated as incidental components selected late in the process, bought in bulk, or sourced purely on unit price. Yet, when these small parts underperform, the results are anything but incidental. Sagging doors, binding gates, or system-level compliance failures can trace back to hinges that weren’t built to withstand the application.

Read More

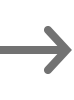

In demanding construction and engineering projects, the word “heavy-duty” can feel like a reassuring shorthand, but when the definition changes from phase to phase, it becomes little more than a label. Across architecture, engineering, fabrication, and installation, the term is used inconsistently without a universal benchmark or supporting data. This lack of clarity introduces risks, especially in high-load and high-cycle applications where even a minor hinge specification mismatch can have serious consequences

Read More

In high-stakes construction, programme certainty depends on seamless coordination from early design through to final handover. But even minor components, like heavy-duty hinges, can introduce costly delays when they don’t align with the actual conditions of the build. When standard hinges are forced into non-standard applications, problems start early and compound with every phase. Approval cycles stall, fabrication teams make adjustments on the fly, and installers lose time correcting misalignments. What should be a straightforward detail becomes a persistent risk. Custom hinge manufacturers, such as Kiesler Machine UK, help eliminate that risk by ensuring the hardware supports the process.

In heavy-use doors, industrial enclosures, and large-format architectural builds, hinges often carry more responsibility than they get credit for. When the wrong hardware is specified, the entire system can suffer from misalignment, premature wear, and complete mechanical failure. Performance isn’t optional for UK-based engineers, architects, and fabricators working on high-load or precision-critical applications. Kiesler Machine provides direct access to American-made door hinges built to deliver lasting reliability, fit-for-purpose strength, and seamless design adaptability

Read More

.png)

When doors weigh several tonnes, when alignment is critical, or when security can’t be compromised, the hinge becomes a major structural asset. Buyers seeking trusted reliability, documented integrity, and long-term durability turn to heavy-duty American-made hinges.

Read More

When it comes to the functionality and reliability of countless structures and devices across various industries, the role of hinges cannot be overlooked.

Read More

Galvanized steel gate hinges are widely used in residential and commercial applications due to robustness, affordability, aesthetic appeal, and benefits they offer.

Read More